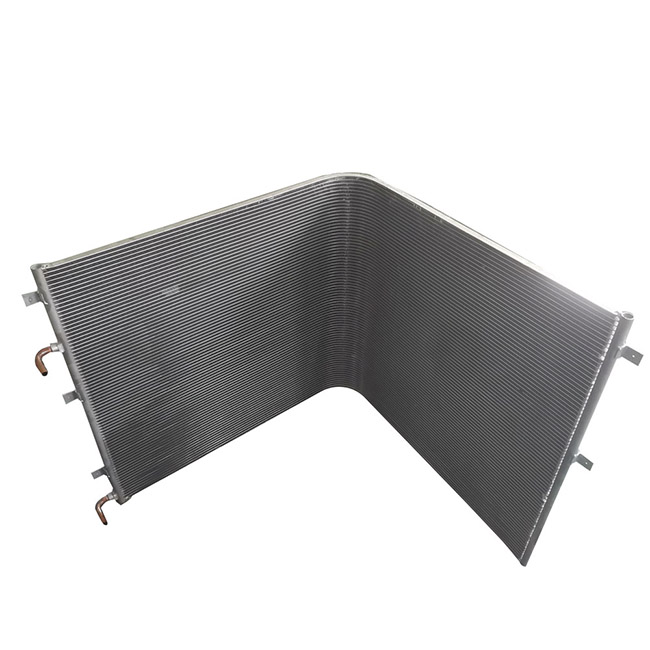

Microchannel Condensing Core

Microchannel Condensing Coil

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

Why Shenglin?

1. Provide non-standard product customization and able to develop new products.

2. Set up a high-tech product research and development center, 16 professional technical R&D experts, the team includes various experts in mechanical engineering, automatic control, system design, cryogenic engineering, testing, etc. And maintain close cooperation with Xi'an Jiaotong University and other Chinese higher education institutions for a long time.

3. At present, the production capacity can reach 1 million pcs a year.

2. Products are compatible with all common refrigerants (R410A, R134a, R22, R407C, R404).

3. Max. production size: 6000*1200mm(L*H).

4. Can offer L, U or C shape bending products.

5. Products can be with e-coating, epoxy, powder coating or normal painting treatment.

2. ISO 9001:2015

2. Respond to inquiries within 24 hours on weekdays and 48 hours on holidays

3. Product lead time normally is about 30 days.

Advantage

1. High heat exchange efficiency.

2. High thermal response rate and good controllability.

3. Low noise, stable operation.,

4. Good pressure bearing capacity.

5. Corrosion resisting.

6. Cost saving, low material consumption under the same heat exchange requirements.

Condenser

Flat tube specs: 12mm, 16mm, 18mm, 20mm, 25.4mm, 32mm and 36mm

Header tube specs: 16mm, 20mm, 22mm, 25mm, 30mm and 40mm

Technology

Parallel arrangement of flat tubes enlarge refrigerant circulation area

1. Provide non-standard product customization and able to develop new products.

2. Set up a high-tech product research and development center, 16 professional technical R&D experts, the team includes various experts in mechanical engineering, automatic control, system design, cryogenic engineering, testing, etc. And maintain close cooperation with Xi'an Jiaotong University and other Chinese higher education institutions for a long time.

3. At present, the production capacity can reach 1 million pcs a year.

Product

1. Provide non-standard product customization.2. Products are compatible with all common refrigerants (R410A, R134a, R22, R407C, R404).

3. Max. production size: 6000*1200mm(L*H).

4. Can offer L, U or C shape bending products.

5. Products can be with e-coating, epoxy, powder coating or normal painting treatment.

Use

MCHE is mainly used in heat exchange applications such as household air conditioners, commercial air conditioners, auto air conditioners, freezing and refrigeration system, computer room air conditioners, heat pumps, chillers, laundry dryers, etcQuality

1. Production 100% pass water or helium inspection test, ensure there is no leak products.2. ISO 9001:2015

Service

1. Offer MCHE drawing design service.2. Respond to inquiries within 24 hours on weekdays and 48 hours on holidays

3. Product lead time normally is about 30 days.

Advantage

1. High heat exchange efficiency.

2. High thermal response rate and good controllability.

3. Low noise, stable operation.,

4. Good pressure bearing capacity.

5. Corrosion resisting.

6. Cost saving, low material consumption under the same heat exchange requirements.

Condenser

Flat tube specs: 12mm, 16mm, 18mm, 20mm, 25.4mm, 32mm and 36mm

Header tube specs: 16mm, 20mm, 22mm, 25mm, 30mm and 40mm

Technology

Integral brazing, low thermal contact resistance, can improve the heat transfer performance perfectly, AL-AL structure, without electric potential difference, high corrosion resistance.

Smaller diameter, many tube holes and large internal surface intensify unit capacity as per volume.

Small cross sectional area, low air flow resistance, small eddy area, low noise.

Parallel arrangement of flat tubes enlarge refrigerant circulation area

Adjust the position and baffles to adapt to the refrigerant phase transition and optimize heat transfer and pressure drop.

The structure effectively breaks air thermal boundary layer, reduce heat exchanging resistance.

Waving path makes the contact longer to intensify heat exchanging.

anterior:ninguno

+Newsmore

- 06 Feb,2024Happy Chinese New Year 2024!

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site